Filter

Original replacement filters or cheaper counterfeit products?

Nowadays it is easy to purchase cheaper filters on the internet. These imitations might fit into your unit, but may otherwise have almost nothing in common with the original part. Often the end customer cannot see any difference in the product, only in the price. But the price is based on things which the cheap filter simply cannot provide.

So there are good reasons why you should buy original replacement filters:

- The filter used by the equipment manufacturer must be approved with regard to fire protection and hygiene. To receive accreditation, the filter must comply with the building material class B2 and pass a flammability test acc. DIN 4102-1. Furthermore, all substances and materials used in the filter (filter fleece, frames, sealants, adhesives) must be demonstrably free from substances hazardous to health.

- The filters in our equipment are designed for the relevant unit with respect to pressure loss (air volume). Here the filter area must be adapted to the material used. The correct pressure loss over the filter in both flow directions is important for the internal leakage of the unit (pressure differences in the unit) and the air volume ratio (balance between the supply air and extract air). The unit characteristics and the fan activation for air volume control have been determined in extensive laboratory tests and are the basis for catalogues, design tools and the software for controlling the units. Other filters with other properties change the behaviour and the air volumes of the unit definitively. Finding a counterfeit product with the same properties would be like winning the lottery.

- Due to differences in materials or a smaller filter surface, incorrect filters can lead to higher pressure losses. In addition to 2.), a higher pressure loss also means the unit will consume more electricity. This is because the effort needed for the fan to transport the air is increased.

- Equipment manufacturers must provide evidence and documentation for the filter classes. They are inspected by market surveillance authorities and must therefore also check their suppliers to ensure reliable and consistent quality.

- Fine filters must be sealed to the housing, so that no unfiltered air can flow past the filter. The higher the filter class, the better the seal needs to be. The original part has the appropriate seal for the unit!

Air filters are essential elements in ventilation and air-conditioning systems to ensure good indoor air quality and system hygiene. Since 01.07.2018, the testing standards and the qualifications of air filters have changed from EN 779 to ISO 16890.

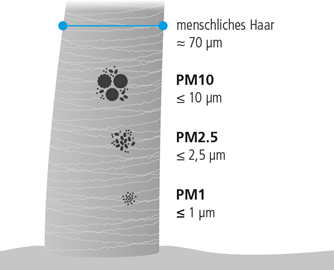

The new ISO 16890, unlike EN 779, evaluates the effectiveness of air filters against the different particulate matter fractions PM1, PM2.5, PM10 and Coarse (fine dust up to 1μm, up to 2.5 μm, up to 10 μm and coarse dust). These PM (Particulate Matter) fine dust values are also used analogously in the evaluation of outdoor air quality. A filter can therefore be selected to match the existing outside air quality.

The filter class groups ISO ePM1, ISO ePM2.5, ISO ePM10, and coarse dust with ISO coarse have replaced the previous filter classes G1 to F9. With the new test standard and its classification system, operators and planners of ventilation and air-conditioning systems can select filter solutions that meet their needs much more easily than with EN 779:2012. In the new testing and classification procedure, the separation behavior is determined with regard to all particle sizes between 0.3 and 10 µm occurring in the outside air, instead of exclusively with particles of size 0.4µm, as was previously the case. This means that the standard is more closely aligned with real-life operating conditions.

When selecting filters in relation to the desired air quality, the new group classification is much more user-friendly. There are four filter groups for which an identification requirement is given with the percentage collection efficiency of the filter in the associated spectrum.

Example: Class ISO ePM1 75% has a collection efficiency (e) against particles ≤ 1 µm of min. 75%. Filters whose collection efficiency is lower than 50% for PM10 are assigned to ISO coarse dust filters.

| Class | Efficiency range | Example particles / fine dust |

| ISO ePM1 | ePM1.min >= 50% | viruses, bacteria, nanoparticles, soot (from fossil fuels), sea salt, oil mist |

| ISO ePM2,5 | ePM2.5,min >= 50% | bacteria, fungal & mold spores, pollen, toner dust |

| ISO ePM10 | ePM10 >= 50% | pollen, rock dust, dust from field cultivation |

| ISO Coarse | ePM10 <50% | sand, lint, flying seedlings, hair, etc. |

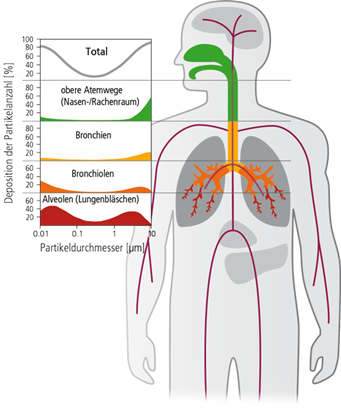

The human body absorbs a variety of particles and dusts through the air we breathe. In particular, small particle fractions make up the majority of these particles and can reach the blood and organs via the alveoli. Filters within the scope of ISO 16890 reduce particle quantities in the range >0.3 µm by up to >90%.

A large number of directives, standards and regulations refer to the filter classification of EN 779 and will probably only be able to be successively over the next few years. Therefore, the question of comparability increasingly arises when air filters with a new classification are used.

A simple justified translation from old to new classes fails because of the different evaluation methodology. A correct translation must be made in the future in the respective application standard for the filters.

Orientation guide for comparison of filter classes old and new:

| EN 779: 2012 | ePM 1 | ePM 2,5 | ePM 10 |

| M5 | 5% - 35% | 10% - 45% | 40% - 70% |

| M6 | 10% - 40% | 20% - 50% | 60% - 80% |

| F7 | 40% - 65% | 65% - 75% | 80% - 90% |

| F8 | 65% - 90% | 75% - 95% | 90% - >95% |

| F9 | 80% - 90% | 85% - 95% | 90% - >95% |