FAQ

Original replacement filters or cheaper counterfeit products?

Nowadays it is easy to purchase cheaper filters on the internet. These imitations might fit into your unit, but may otherwise have almost nothing in common with the original part. Often the end customer cannot see any difference in the product, only in the price. But the price is based on things which the cheap filter simply cannot provide.

So there are good reasons why you should buy original replacement filters:

- The filter used by the equipment manufacturer must be approved with regard to fire protection and hygiene. To receive accreditation, the filter must comply with the building material class B2 and pass a flammability test acc. DIN 4102-1. Furthermore, all substances and materials used in the filter (filter fleece, frames, sealants, adhesives) must be demonstrably free from substances hazardous to health.

- The filters in our equipment are designed for the relevant unit with respect to pressure loss (air volume). Here the filter area must be adapted to the material used. The correct pressure loss over the filter in both flow directions is important for the internal leakage of the unit (pressure differences in the unit) and the air volume ratio (balance between the supply air and extract air). The unit characteristics and the fan activation for air volume control have been determined in extensive laboratory tests and are the basis for catalogues, design tools and the software for controlling the units. Other filters with other properties change the behaviour and the air volumes of the unit definitively. Finding a counterfeit product with the same properties would be like winning the lottery.

- Due to differences in materials or a smaller filter surface, incorrect filters can lead to higher pressure losses. In addition to 2.), a higher pressure loss also means the unit will consume more electricity. This is because the effort needed for the fan to transport the air is increased.

- Equipment manufacturers must provide evidence and documentation for the filter classes. They are inspected by market surveillance authorities and must therefore also check their suppliers to ensure reliable and consistent quality.

- Fine filters must be sealed to the housing, so that no unfiltered air can flow past the filter. The higher the filter class, the better the seal needs to be. The original part has the appropriate seal for the unit!

Air filters are essential elements in ventilation and air-conditioning systems to ensure good indoor air quality and system hygiene. Since 01.07.2018, the testing standards and the qualifications of air filters have changed from EN 779 to ISO 16890.

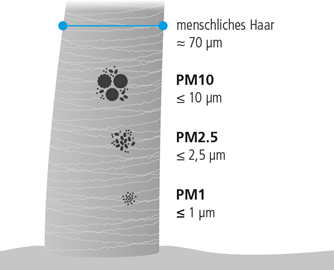

The new ISO 16890, unlike EN 779, evaluates the effectiveness of air filters against the different particulate matter fractions PM1, PM2.5, PM10 and Coarse (fine dust up to 1μm, up to 2.5 μm, up to 10 μm and coarse dust). These PM (Particulate Matter) fine dust values are also used analogously in the evaluation of outdoor air quality. A filter can therefore be selected to match the existing outside air quality.

The filter class groups ISO ePM1, ISO ePM2.5, ISO ePM10, and coarse dust with ISO coarse have replaced the previous filter classes G1 to F9. With the new test standard and its classification system, operators and planners of ventilation and air-conditioning systems can select filter solutions that meet their needs much more easily than with EN 779:2012. In the new testing and classification procedure, the separation behavior is determined with regard to all particle sizes between 0.3 and 10 µm occurring in the outside air, instead of exclusively with particles of size 0.4µm, as was previously the case. This means that the standard is more closely aligned with real-life operating conditions.

When selecting filters in relation to the desired air quality, the new group classification is much more user-friendly. There are four filter groups for which an identification requirement is given with the percentage collection efficiency of the filter in the associated spectrum.

Example: Class ISO ePM1 75% has a collection efficiency (e) against particles ≤ 1 µm of min. 75%. Filters whose collection efficiency is lower than 50% for PM10 are assigned to ISO coarse dust filters.

| Class | Efficiency range | Example particles / fine dust |

| ISO ePM1 | ePM1.min >= 50% | viruses, bacteria, nanoparticles, soot (from fossil fuels), sea salt, oil mist |

| ISO ePM2,5 | ePM2.5,min >= 50% | bacteria, fungal & mold spores, pollen, toner dust |

| ISO ePM10 | ePM10 >= 50% | pollen, rock dust, dust from field cultivation |

| ISO Coarse | ePM10 <50% | sand, lint, flying seedlings, hair, etc. |

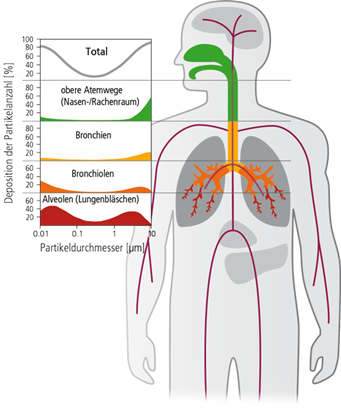

The human body absorbs a variety of particles and dusts through the air we breathe. In particular, small particle fractions make up the majority of these particles and can reach the blood and organs via the alveoli. Filters within the scope of ISO 16890 reduce particle quantities in the range >0.3 µm by up to >90%.

A large number of directives, standards and regulations refer to the filter classification of EN 779 and will probably only be able to be successively over the next few years. Therefore, the question of comparability increasingly arises when air filters with a new classification are used.

A simple justified translation from old to new classes fails because of the different evaluation methodology. A correct translation must be made in the future in the respective application standard for the filters.

Orientation guide for comparison of filter classes old and new:

| EN 779: 2012 | ePM 1 | ePM 2,5 | ePM 10 |

| M5 | 5% - 35% | 10% - 45% | 40% - 70% |

| M6 | 10% - 40% | 20% - 50% | 60% - 80% |

| F7 | 40% - 65% | 65% - 75% | 80% - 90% |

| F8 | 65% - 90% | 75% - 95% | 90% - >95% |

| F9 | 80% - 90% | 85% - 95% | 90% - >95% |

In the extract air rooms, a fan removes the extract air and guides it out of the building as exhaust air. The air heats up on its way to the extract air rooms, taking odours and moisture with it as it goes. The resulting underpressure pulls the outdoor air into the living and sleeping areas through a supply air vent. The supply air is filtered as it enters through the outdoor air vent.

To help you find the right duct system and the right size, here we give you a few simple design rules for determining the overall air volumes needed in an apartment or a singlefamily house.

The air volumes for the supply air rooms are specified depending on the planned occupancy, whereby the air volumes should not fall below a minimum volumetric flow of 15 m³/h.

For acoustic reasons, a supply or extract air valve should be specified with a maximum of 40 m³/h. This is unless the valve is explicitly intended for higher flow rates. The air speed in the ducts should be max. 3 m/s. The following tables show the max. volumetric flows for an air speed of 3 m/s for our various duct systems.

You can use these to roughly work out the size and number of ducts and valves you need.

Locating valves

For acoustic reasons, valves should never be installed in the corners of rooms, but instead be at least 1 m away from the wall.

Wherever possible, you should always plan to install supply air valves in the ceiling, or in the wall just below the ceiling. This gives the most effective and comfortable distribution of air in the room. When selecting valves, please consider whether the valve geometry is suitable for the ceiling or the wall.

Extract air valves should also be installed in the ceiling, or close to the ceiling, so that it is always possible to remove the warmest and most humid air from the room. Here, too, the best location is the centre of the room.

If you adhere to these requirements, you will have a system with an external pressure loss of around 60 - 80 Pa. Using the overall air volume and the external pressure loss, you can configure the appropriate unit on our homepage. It is even simpler if you use the specified operating point for our units here in the catalogue: air volume at 50 Pa.

Rotary heat exchanger

As well as heat (sensible heat), rotary heat exchangers are also able to transmit moisture (latent heat). For use in singlefamily houses or dwellings with sensible efficiencies of up to more than 85 per cent.

Heat transfer

The lamellar structure of the rotor (similar to corrugated paper) and the continuous rotary motion between the warm and cold air currents result in the rotor heating up in the extract air. In winter this heat is transferred to the cold supply air. This effect can be used in reverse in summer, because heat from the outdoor air is transferred to the cooler extract air. This enables a cooling effect to be achieved in summer, or also it can be used to recover cooling energy in air-conditioned buildings.

Moisture transmission via a condensation rotor

The heat exchange matrix is made from pure aluminium which transfers moisture precisely at the moment when condensation forms on the extract air side and is then reabsorbed by the outdoor air. For large temperature differences, the degree of recovered moisture can rise above 60 per cent. With our rotors, moisture is primarily transferred when it is needed, i.e. in winter. This enables problems with overly-dry air to be reduced or even avoided altogether. The moisture transfer can be controlled by adjusting the rotor speed.

Entrained rotation – internal leakage

The rotor rotation can result in small amounts of extract air entering the supply air (entrained rotation). A combination of air leakage in the housing and the rotor speed, in conjunction with the pressure differential of the unit (caused by filters, for example), can result in a certain amount of extract air being transferred to the supply air. In general, our equipment has an internal leakage rate of less than 5 per cent. This even falls to below 3 per cent for equipment certified for use in passive houses. This means that nowadays, units with a rotor are certainly comparable with plate heat exchangers, at least concerning internal leakage.

Frost protection

Thanks to the transfer of moisture, it is not necessary to drain away condensation in residential buildings. This means the ventilation unit does not need to be connected to a waste water pipe. Also, down to around -20 °C, the rotor does not freeze while transferring condensation, making frost protection for the heat exchanger unnecessary. Therefore, the entire capability of the heat exchanger can be exploited when outside temperatures are low. The colder the better.

Counter flow heat exchanger

Aluminium and plastic counter flow heat exchangers transfer heat (sensible heat) and are able to achieve efficiencies of over 90 per cent. Heat transfer In plate heat exchangers, the air flows through a series of parallel plates. Here supply air and extract air always. flow alternately on opposite sides. The heat energy is transferred through the plate from the warm air current to the cold air current.

Without moisture transfer

If conventional aluminium or plastic plate heat exchangers are used, the resulting condensate must be removed from the unit via a waste water pipe. The siphon must always be filled with water to prevent air from being sucked through the duct system.

Airtightness

Supply air and extract air are completely separate from each other so, in theory, there is no portion of extract air in the supply air. In practice however, there can be internal leakages due to a combination of manufacturing tolerances of approx. 0.8 per cent for plate heat exchangers (manufacturer's specifications) and leakages in the housing, depending on the pressure difference in the unit. Here too, the limit for internal leakage is 5 per cent and 3 per cent for a passive house.

Frost protection

The higher the efficiency of the heat exchanger, the more condensate can form when temperature differences are large. The efficiency also affects the temperature below which the heat exchanger must be protected from frost, i.e. when the condensate starts to freeze. For high-performance counter flow heat exchangers with efficiencies of around 90 per cent, this may already be the case for outside temperatures below -3 °C. The lower the efficiency, the lower the freezing point. This also means the energy expenditure for frost protection varies correspondingly. For reliable frost protection, and to prevent too much heat being extracted from the heat exchanger, the outdoor air can either be preheated, or guided past the heat exchanger via a bypass and then over a heater. Another option is often used: the supply air fan is throttled, creating an imbalance between the supply air and the extract air. However this no longer works for modern, airtight houses. Frost protection can be achieved without using too much energy by investing in a brine-geothermal heat exchanger. No matter how it is done, frost protection costs money and energy! Special types of plate heat exchangers, such as themembrane counter flow heat exchanger, can also transfer moisture as well as heat. However the sensible heat transmission efficiency is reduced to around 75 per cent, i.e. below that of the rotors.

With moisture transfer

Membrane exchangers can transfer moisture and do not need to be connected to a waste water pipe. Depending on the humidity difference, moisture can also be transferred from the outdoor air to the extract air in summer. However, membranes are subject to wear; the pores start to close up and eventually the heat exchanger must be replaced. This means that the original moisture transfer performance reduces continually over time.

Frost protection

At around -8 °C, the frost point of membrane heat exchangers is somewhat lower than that of aluminium or plastic heat exchangers. Just like for aluminium or plastic heat exchangers, energy must be added to protect the heat exchanger from freezing when outside temperatures are low.

Conclusion

Every type of heat exchanger has advantages and disadvantages, which are more or less significant depending on the requirements. A plate heat exchanger can make the best use of its high efficiency if the outside temperature does not fall (or falls only briefly) below its specific frost point. Then frost protection is unnecessary and, due to the mild climate (not colder than around -3°C), the indoor climate does not become too dry, even without moisture transfer. A membrane heat exchanger plays to its strengths wherever as much moisture as possible is to be transferred continuously. Aluminium or plastic heat exchangers are often replaced by membrane heat exchangers after around two years, once the moisture from construction has gone. However, the moisture transfer cannot be controlled here and the membrane gradually closes. A rotor performs most strongly in climates down to around -20 °C. Here the rotor is able to generate maximum heat recovery without any frost protection at all, as well as transferring moisture as needed. Nowadays internal leakages are no longer a problem, since they are comparable with other heat exchangers. Within a dwelling a slight transfer of odour is unimportant, since the proportion transferred via the ventilation system is considerably smaller than, for example, via doors, clothes or the body of air able to move between rooms. With the open plan (living-eating area) designs common today, this is no longer of any significance.

The EU sets minimum energy efficiency requirements for the appropriate productsvia the "Directive 2009/125/EC establishing a framework for the setting of eco-design requirements for energy-related products" – or Ecodesign Directive or ErP Directive for short.

The energy label should permit the end user to compare products easily, enabling them to select energy-efficient products. In contrast to other electrical equipment, the energy classes on the labels of residential ventilation equipment are determined by a calculated parameter, the specific energy consumption (SEC). This value should display the energy-saving potential of the equipment used in kilowatt hours per m² per year.

New requirements for ventilation and air-conditioning

Fans EU 327/2011 (B2B, no label)

• Since 2013, minimum requirements apply for fans above 125 Watts regarding energy efficiency

• From January 1, 2015, these requirements have become significantly more stringent

Central ventilation and air conditioning units EU 1253/2014 (B2B, no label)

• Since January 1, 2016, minimum requirements apply regarding

• fan power consumption and

• heat recovery efficiency

Residential ventilation equipment EU 1253/2014 and 1254/2014 (B2C, label)

• Minimum requirements from January 1, 2016: The units must save at least as much primary energy (electricity and heat) as they use (electricity)

• Minimum requirements from January 1, 2018: The units must save significantly more primary energy than they use – the ventilation heat requirement of the residential building is approximately halved

• Energy efficiency label from A+ to G (see Table)

Air conditioners EU 206/2012 (B2C, label)

• Since January 1, 2013, units with a cooling performance up to 12 kW are classified in energy efficiency classes from A+++ to D

• Units in cooling mode must fulfil at least the requirements of energy efficiency class A

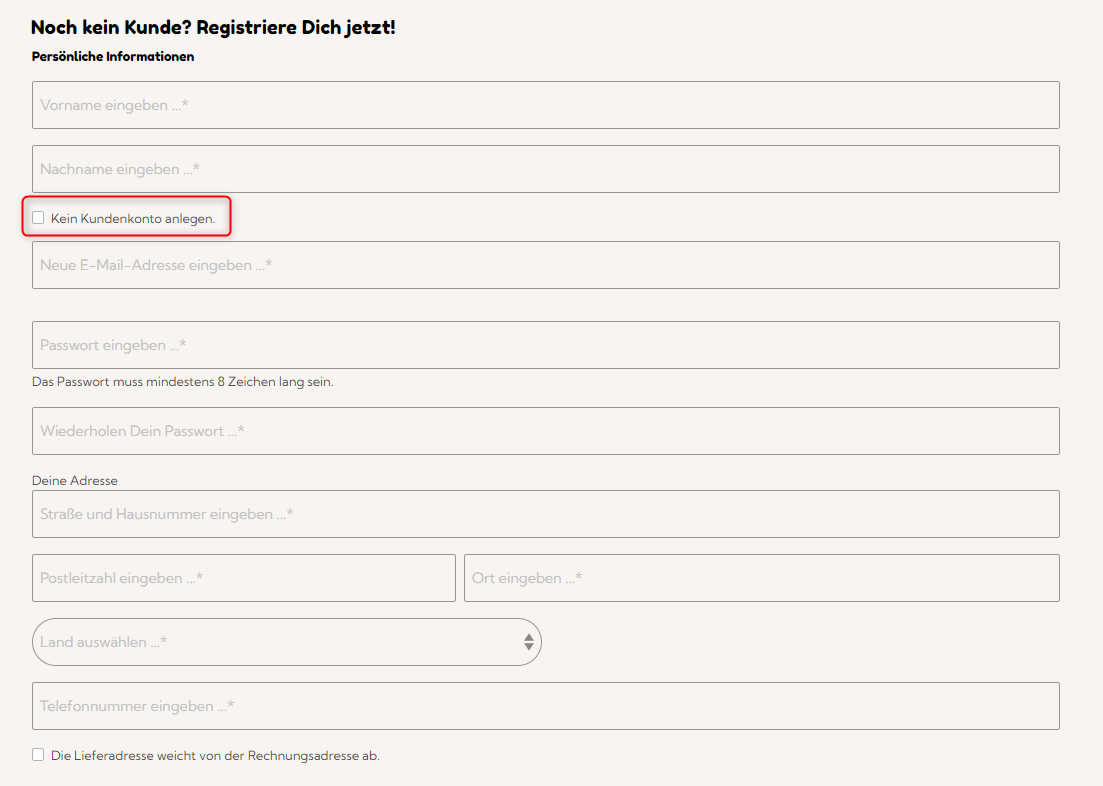

Click on the registration button to access the registration form. Fill in the required information (marked with *). Agree to the general terms and conditions and confirm your entry.

If you have forgotten your password, simply click on the link "I have forgotten my password?" when logging in and enter your e-mail address in the following window. You will immediately receive an e-mail from us containing a link to change your password. Please click on this link or copy the URL into your browser to call up the page. You can now set a new password for your customer account. Your old password will only become invalid once you have entered a new password

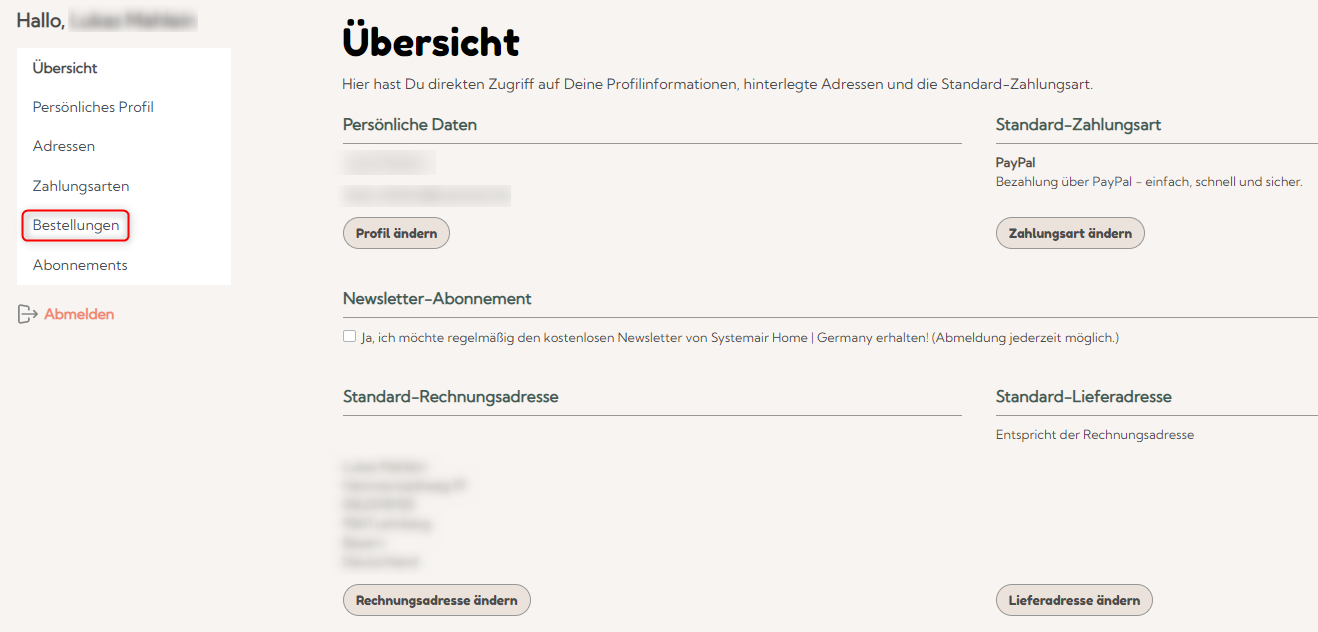

You can change your delivery address at any time in the "Customer area" under "Overview". Click on the "Change delivery address" button under "Standard delivery address", enter the new data in the form under your current delivery address and click on "Save address".

Simply go to your customer area and click Log off.

By ticking the box "Do not create a customer account" during the ordering process, you can complete an order without registering.

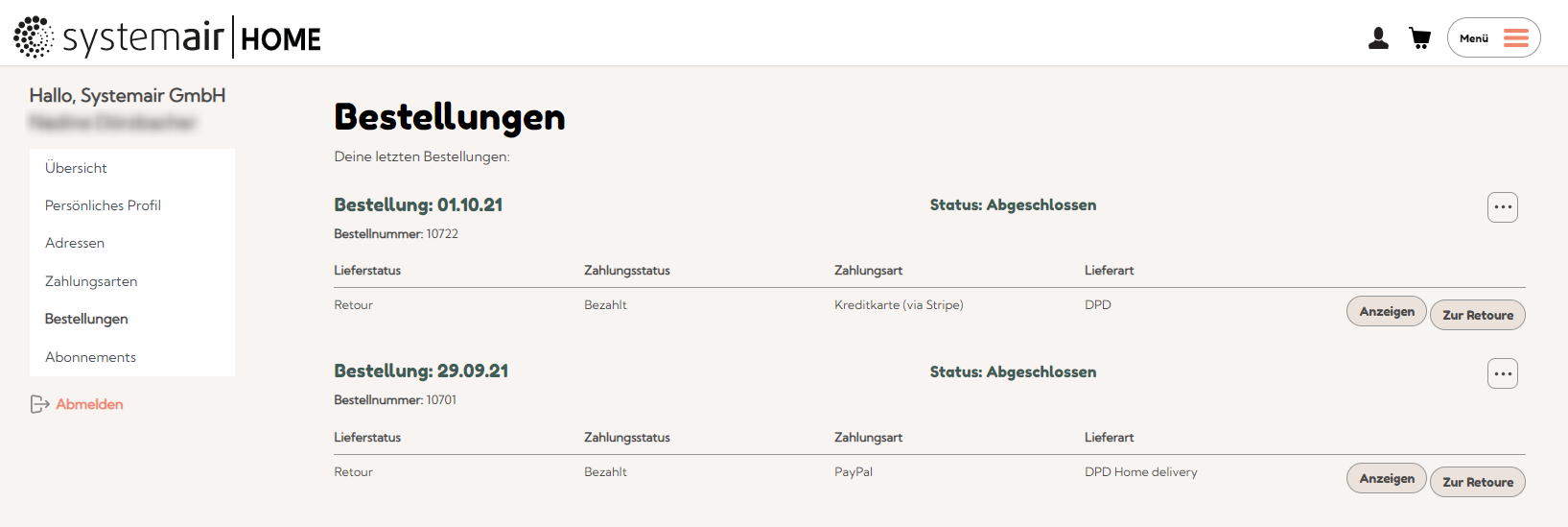

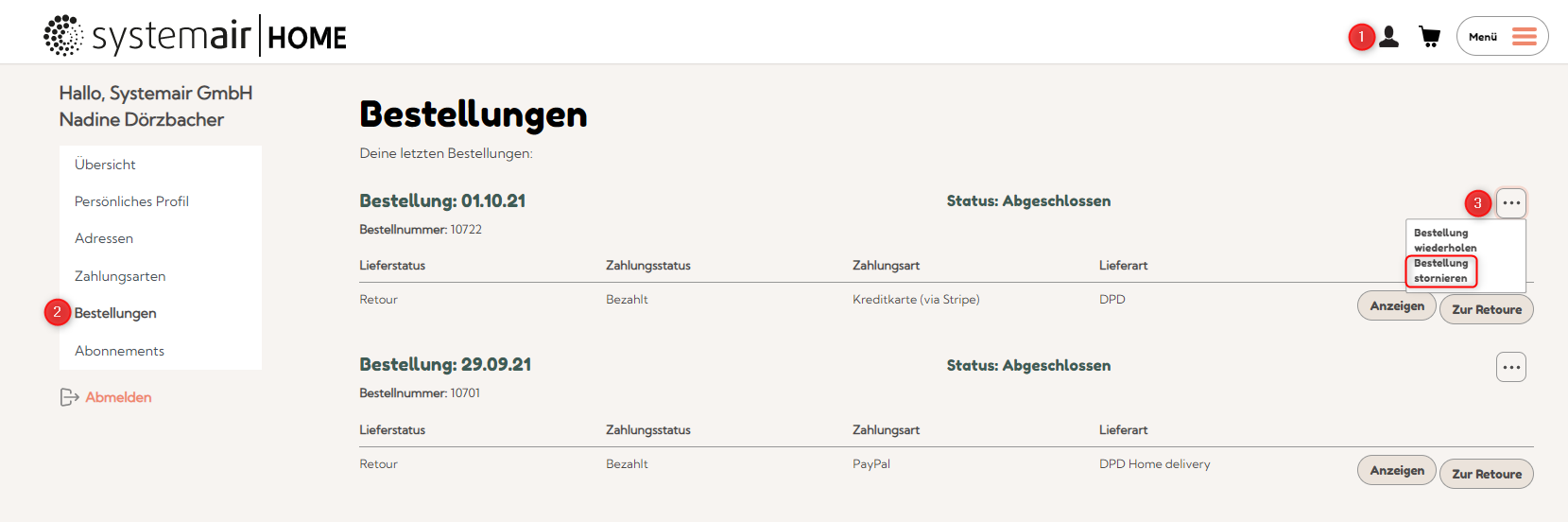

To view your orders, log in to your customer area with your user data and click on the "Orders" button. There you will find your orders with all relevant information and their order status.

To cancel your orders, log in to your customer area with your user data and click on the "Orders" button. The three dots behind your order will take you to the "Cancel order" button. You must then confirm your entry in the next window.

To create a return, log in to your customer area with your user data and select "Orders". Here you can create a return for the individual orders using the "To return" button.